DPF Cleaners: Unlocking the Power of Diesel Particulate Filter Maintenance

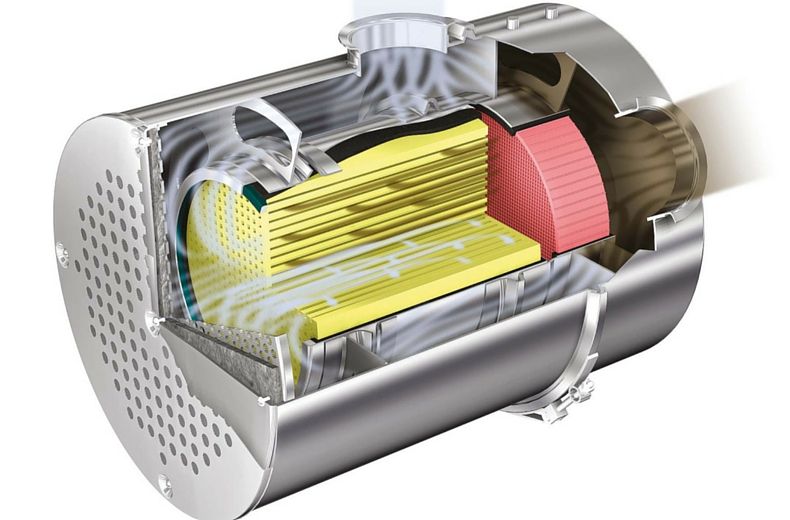

In the realm of diesel engines, preserving peak performance while adhering to strict emissions standards is a priority for vehicle owners and operators. One essential component that plays a pivotal role in achieving this balance is the Diesel Particulate Filter (DPF). This article explores the world of DPF cleaners, shedding light on their significance, how they work, and their role in maintaining DPF efficiency and compliance with environmental regulations.

The Crucial Role of DPFs:

A Diesel Particulate Filter (DPF) is a critical emissions control device installed within the exhaust system of diesel-powered vehicles and machinery. Its primary function is to capture and reduce harmful particulate matter (PM) emissions, such as soot and ash, generated during the combustion process.

Maintaining a clean DPF is vital for multiple reasons, including optimizing fuel efficiency, reducing maintenance costs, and ensuring adherence to strict emissions regulations that can result in substantial penalties for non-compliance.

The Power of DPF Cleaners:

DPF cleaners are specially formulated chemical solutions designed to break down and remove accumulated soot and ash within the DPF, restoring it to peak performance. These cleaners offer several advantages:

1. Improved Fuel Efficiency:

Cleaning the DPF with the appropriate cleaner can lead to increased fuel efficiency by reducing exhaust system restrictions caused by soot buildup.

2. Extended DPF Lifespan:

Regular use of DPF cleaners can prolong the lifespan of the filter by preventing excessive clogging and the need for premature replacement.

3. Enhanced Emissions Control:

Clean DPFs ensure that diesel engines maintain compliance with strict emissions standards, contributing to a cleaner environment and avoiding costly fines.

4. Cost Savings:

By preventing the need for frequent DPF replacements and avoiding potential fines, DPF cleaners can translate into significant cost savings for vehicle owners and operators.

How DPF Cleaners Work:

DPF cleaners work through a chemical reaction that targets the soot and ash accumulated within the filter. Here’s a simplified overview of the process:

Softening and Loosening: DPF cleaners contain active ingredients that soften and loosen the stubborn soot and ash deposits clinging to the filter’s walls.

Combustion Promotion: Some cleaners encourage the combustion of trapped soot by raising the temperature within the filter. This process burns off the accumulated particles, effectively cleansing the DPF.

Effluent Disposal: The resulting ash and soot particles are converted into gases and ash residues that can exit the exhaust system safely without causing blockages.

Using DPF Cleaners:

Using DPF cleaners is a straightforward process:

Identification: First, identify the appropriate DPF cleaner for your specific vehicle or equipment, as different formulations may be required for various engine types and DPF designs.

Application: Follow the manufacturer’s instructions for application, typically involving the injection of the cleaner into the exhaust system or the introduction of the cleaner through the fuel tank.

Drive or Operate: After application, drive the vehicle or operate the machinery to allow the cleaner to work its magic. It typically takes some time for the cleaning process to be effective.

Monitor Performance: Observe improvements in fuel efficiency, engine performance, and reduced emissions after using the DPF cleaner.

DPF cleaners are valuable tools for diesel engine owners and operators, helping to ensure peak performance, extend the lifespan of the DPF, and maintain compliance with stringent emissions standards. Regular use of these cleaners can lead to significant cost savings and contribute to a cleaner environment. Always consult the manufacturer’s recommendations and guidelines when selecting and using DPF cleaners to ensure optimal results for your diesel-powered vehicles and equipment.