Prepregs in Advanced Manufacturing: The Future of Composite Technology

In today’s high-tech industries, prepregs have become essential materials that redefine how advanced components are built. Combining reinforcing fibers with partially cured resin systems, these composites provide superior strength, precision, and efficiency. From aerospace engineering to automotive and industrial production, epoxy prepreg, aerospace prepreg, rapid-cure prepreg, and carbon fiber prepreg represent the most advanced solutions available for modern manufacturing.

The Power of Epoxy Prepreg

Epoxy prepreg is a pre-impregnated fiber material that uses epoxy resin as its binding system. The resin is partially cured, allowing it to remain tacky and flexible until final processing. This structure enables perfect fiber alignment, controlled resin content, and minimal voids, resulting in highly consistent and reliable parts.

Engineers value epoxy prepreg for its outstanding mechanical performance, temperature stability, and adhesion to different fibers such as carbon or glass. It is used in aircraft components, wind turbine blades, industrial molds, and even consumer electronics where precision and durability are crucial. Its versatility and ease of processing make it a leading choice for both prototyping and full-scale production.

Aerospace Prepreg for Maximum Reliability

The aerospace sector demands materials that perform flawlessly in extreme environments. Aerospace prepreg is specifically formulated for such challenges. It combines high-strength carbon fibers with advanced resin systems capable of withstanding extreme temperatures and dynamic loads.

Aerospace prepreg offers predictable mechanical properties, fatigue resistance, and long-term stability under stress. Aircraft structures, satellite components, and UAV parts benefit from these composites because they deliver exceptional strength-to-weight ratios. For aerospace manufacturers, these materials reduce weight, improve fuel efficiency, and ensure safety without compromise.

Rapid-Cure Prepreg – Fast and Efficient Production

In industries where time equals money, rapid-cure prepreg provides a solution that balances performance with speed. Traditional curing processes often take hours, but rapid-cure prepreg systems are engineered to cure within minutes. This makes them ideal for automotive parts, sports equipment, and other high-volume applications.

The rapid curing cycle helps manufacturers achieve higher throughput while maintaining the structural quality expected from standard prepregs. These materials are revolutionizing production lines by reducing energy consumption, lowering costs, and enabling on-demand composite manufacturing.

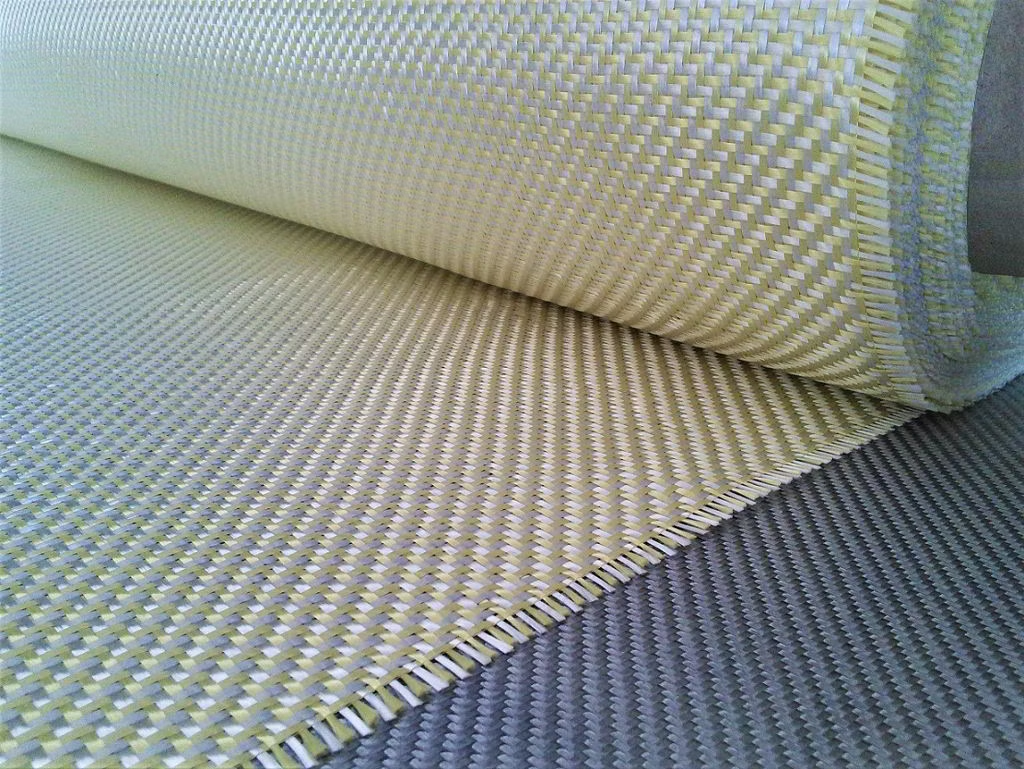

Carbon Fiber Prepreg – The Ultimate Material for Strength and Style

Carbon fiber prepreg combines the aesthetic appeal of carbon fiber with cutting-edge engineering performance. The material delivers extreme stiffness, low weight, and impressive fatigue resistance. Its signature woven texture has also become a visual symbol of high performance and modern design.

Carbon fiber prepreg is used in aerospace, automotive racing, marine structures, and sporting goods. Whether forming the body of a supercar, an aircraft fuselage, or a high-end bicycle frame, these prepregs make it possible to achieve strength levels that metals cannot match, all while maintaining minimal weight.

Advantages of Using Advanced Prepregs

Integrating epoxy prepreg, aerospace prepreg, rapid-cure prepreg, and carbon fiber prepreg in manufacturing processes provides several clear advantages:

• High strength-to-weight ratio – Perfect for reducing component weight without sacrificing performance.

• Excellent consistency – Controlled resin content ensures predictable results across all production batches.

• Shorter cycle times – Especially with rapid-cure variants that reduce processing hours.

• Enhanced durability – Outstanding resistance to fatigue, chemicals, and extreme conditions.

• Design freedom – Suitable for complex geometries and multifunctional structures.

The Future of Prepreg Technology

The next generation of prepreg materials focuses on efficiency and sustainability. Researchers are developing epoxy prepreg systems that cure faster, use less energy, and offer recyclability. Out-of-autoclave processes are also gaining traction, allowing manufacturers to produce high-quality composites without expensive autoclaves.

Aerospace prepreg and carbon fiber prepreg continue to evolve, integrating nano-reinforcements and hybrid fibers for even higher performance. Meanwhile, rapid-cure prepreg is enabling the automotive sector to adopt composite materials on a larger scale than ever before.

Prepreg technology is transforming the landscape of advanced manufacturing. Whether it’s the versatility of epoxy prepreg, the precision of aerospace prepreg, the efficiency of rapid-cure prepreg, or the strength of carbon fiber prepreg, these materials drive innovation across multiple industries. As production methods advance and materials become more sustainable, prepregs will remain the foundation for next-generation engineering and design.